Effluent Treatment has become a nuisance, a thorn in the manufacturing. An unwanted road block in this booming period.

If ETP itself is a thorn, Zero discharge is certainly an ambitious one,

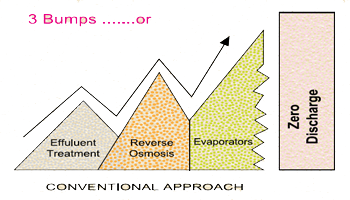

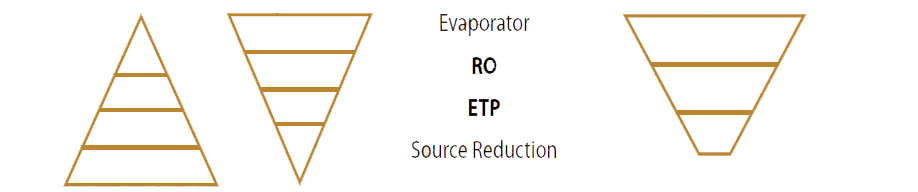

Tackling and achieving the goal of zero discharge is a complex technical and systems challenge – one that JUST ADDITION OF MORE AND MORE EQUIPMENT alone cannot solve.

Many companies kept adding

Thinking it is the last step to Zero discharge…………

Unfortunately they still have miles to go before they reach.....

More and more equipment will not take you to Zero Discharge.

Understanding & Integration of

will certainly get you there.

ROAD MAP TO ZERO DISCHARGE

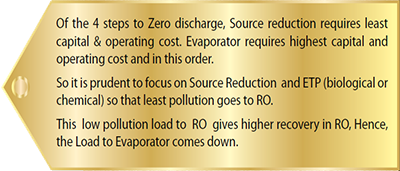

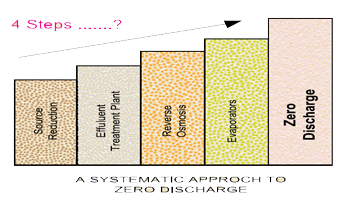

To reach Mt.Everest we have to carry minimum luggage. To reach Zero discharge , Evaporator be given minimum load, As it is the highest consumer of energy.

i.e., RO reject going to Evaporator must be reduced. Our RO design and operation makes it possible by recovering maximum water from the effluent.

Which road you want to archieve Zero Discharge ?

COST DOMINOS

Key to successful zero discharge is minimizing feed to the evaporator. Because of our technology We give maximum recovery in the RO plant. Hence the load to Evaporator decreases.

Conventional Technology is at least 3times costlier than SARTIME Technology

SARTIME TECHNOLOGIES

Conventional End of the pipe approach

Pollution load at each step Cost of treatment at each step

Cost of treatment at each step

SOURCE RED UCTION & HI PER FORMANCE ETP

Source Study & Custom designed ETP

Generally a ETP is designed based on COD or the total chemicals present. Lumping all these chemicals together is the main cause for failure of most of the ETPs.

However, we conduct a detailed study of the Raw materials used, Manufacturing process, Sources of effluent and the existing Treatment methods. We look beyond just the EFFLUENT ANALYSIS.

This type of custom design, gives us an opportunity to reduce the pollution at source considerably, making down stream processing easier and viable. In some cases, we have even eliminated the need for an effluent treatment plant.SARTIME ETP design is based on detailed study of the chemicals in the effluent and not by using a standard formula or sewage design.

Performance of the Treated effluent we have achieved

COD from >20,000mg/lit to <250mg/lit NH3 from 10,000% to <50mg/lit

| Source Reduction | ETP | RO | EVOP | |

|---|---|---|---|---|

| Op. Cost | Nil | X | 3X | 50-80X |

| Cap.Cost | Negligible | X | 2X | 4X |

| Pollution | 30% less | COD | 85-90% | |

| Load | <1000ppm | recovery |

To get good water from effluent, we have degraded some of the most recalcitrant chemicals.

some of them are :

- Butanediol

- Hexamine

- Seracin

- Pentaerythritol

- Amines

- DMF

- DMSO

and many bulk drug conc. effluents

CUSTOMISED RO SYSTEM DESIGN

We have worked with some of the most difficult effluents in the RO plant, making full use of our R&D center.

- >85% of water is Recovered from effluent

- Recovered water (Permeate) has COD <10 ppm

- Membrane life >4 years

- Reduced choking in the evaporator

- No scaling of tubes

- High availability of evaporator and less downtime.

- SARTIME ZLD systems eliminate liquid waste streams from your plant

Robust and Innovative solutions for demanding Applications. Because we have an extensive R&D center for RO plants. Besides building, we also operate plants and this experience helps us to prepare better and anticipate problems for a given effluent, which others do not have an idea.

We have several proven technology installations partnering with many leading Multinationals.Some of the major industries in the world are our clients : Many major pharma, chemical, auto ancillaries manufacturers, textile etc.

Services offered by us :

- Build zero discharge plants.

- Operate the plant 24x7 under O&M contract.

- Troubleshoot existing plants.

- Revamp and Retrofitting existing plants to today’s demand.

- Implement source reduction technologies towards performance improvement of your existing systems.

Because of our good backup service

- Our clients give repeated orders

- Also refer us to other clients.